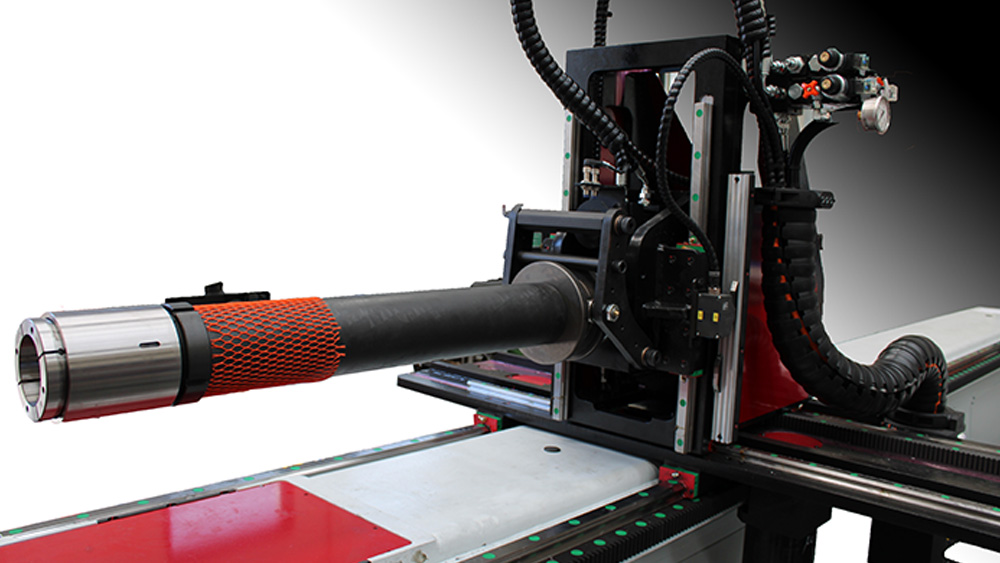

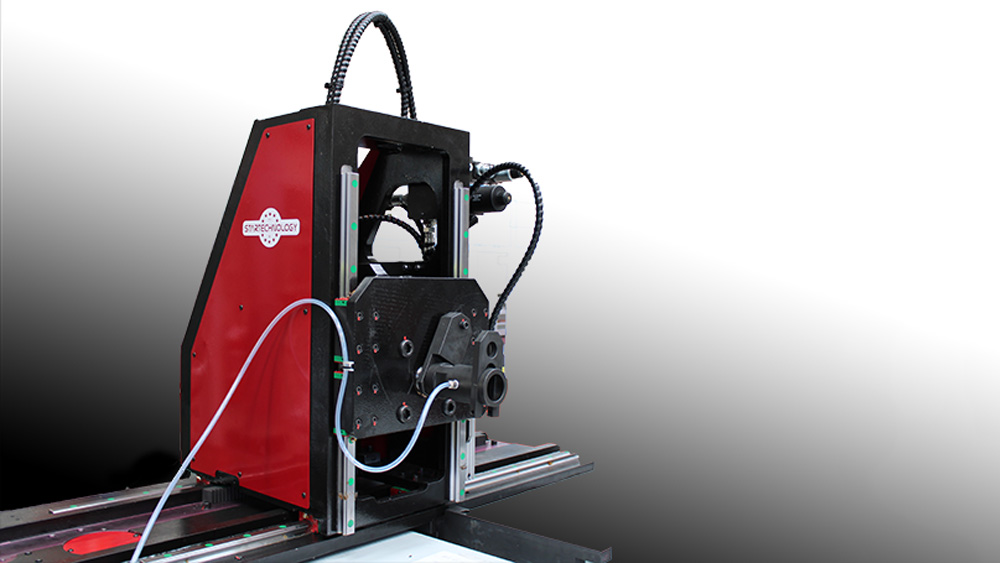

HEAVY BEND 1200 pipe benders can be made on several levels, making them extremely flexible and suitable even for the most complex uses, available in the simplest one-stack models up to the Multi-stacks version which can be integrated with electrical options.

The HEAVY BEND 1200 pipe benders also feature a Dc Bus energy saving system with active current regeneration, which guarantees energy savings of up to 42% of the power absorbed.

The machine control system through a simplified graphic interface allows the creation of cycles through file import and 3D piece creation simulation, for a simple and unique use.

ISO certified system 9001:2008

ISO certified system 9001:2008

Made in Italy

Made in Italy

Technical sheet

Automation levels

HEAVY BEND 120-1P

Caratteristiche

| Axe | Position | Name | Type |

| 1 | Y | BEND | BRUSHLESS |

| 2 | XM | FORWARD | BRUSHLESS |

| 3 | XS | FORWARD | BRUSHLESS |

| 4 | Z | ROTATION | BRUSHLESS |

| 5 | R | HEAD MOVEMENT | MANUAL |

| 6 | AS | TUBE SUPPORT | HYDRAULIC |

| 7 | M | CLAMP | HYDRAULIC |

| 8 | C | SHOULDER | HYDRAULIC |

| 9 | S | FOLLOWING | HYDRAULIC |

| 10 | RM | DIE RETURN | HYDRAULIC |

| 11 | AN | MANDREL | HYDRAULIC |

| 12 | PI | COLLET | HYDRAULIC |

HEAVY BEND 120-2P

Caratteristiche

| Axe | Position | Name | Type |

| 1 | Y | BEND | BRUSHLESS |

| 2 | XM | FORWARD | BRUSHLESS |

| 3 | XS | FORWARD | BRUSHLESS |

| 4 | Z | ROTATION | BRUSHLESS |

| 5 | R | HEAD MOVEMENT | BRUSHLESS |

| 6 | AS | TUBE SUPPORT | HYDRAULIC |

| 7 | V | HEAD HEIGHT | HYDRAULIC |

| 8 | M | CLAMP | HYDRAULIC |

| 9 | C | SHOULDER | HYDRAULIC |

| 10 | S | FOLLOWING | HYDRAULIC |

| 11 | RM | DIE RETURN | HYDRAULIC |

| 12 | AN | MANDREL | HYDRAULIC |

| 13 | PI | COLLET | HYDRAULIC |

HEAVY BEND 120-MP

Caratteristiche

| Axe | Position | Name | Type |

| 1 | Y | BEND | BRUSHLESS |

| 2 | XM | FORWARD | BRUSHLESS |

| 3 | XS | FORWARD | BRUSHLESS |

| 4 | Z | ROTATION | BRUSHLESS |

| 5 | R | HEAD MOVEMENT | BRUSHLESS |

| 6 | AS | TUBE SUPPORT | BRUSHLESS |

| 7 | V | HEIGHT HEAD | BRUSHLESS |

| 8 | M | CLAMP | HYDRAULIC |

| 9 | C | SHOULDER | HYDRAULIC |

| 10 | S | FOLLOWING | HYDRAULIC |

| 11 | RM | DIE RETURN | HYDRAULIC |

| 12 | AN | MANDREL | HYDRAULIC |

| 13 | PI | COLLET | HYDRAULIC |