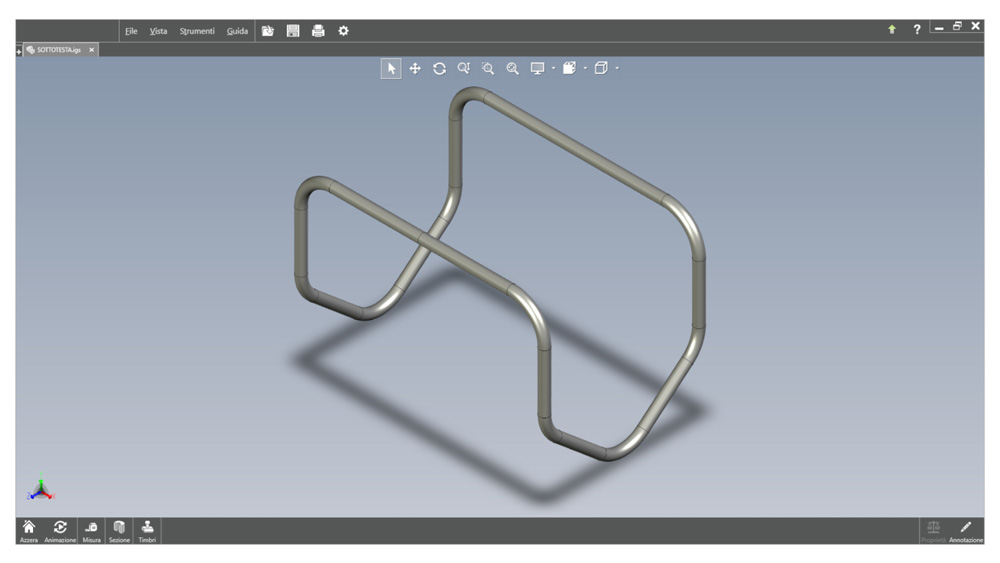

Tube Works is the fastest way to turn your projects into reality; it is an effortless application that allows you to automatically extract L - R - A and X - Y - Z data from STEP and IGES files and transfer them directly to your STAR TECHNOLOGY machine.

Loaded the .STEP or .IGES file a simple click will be enough to transfer the bending data to the bender immediately after the file opening.

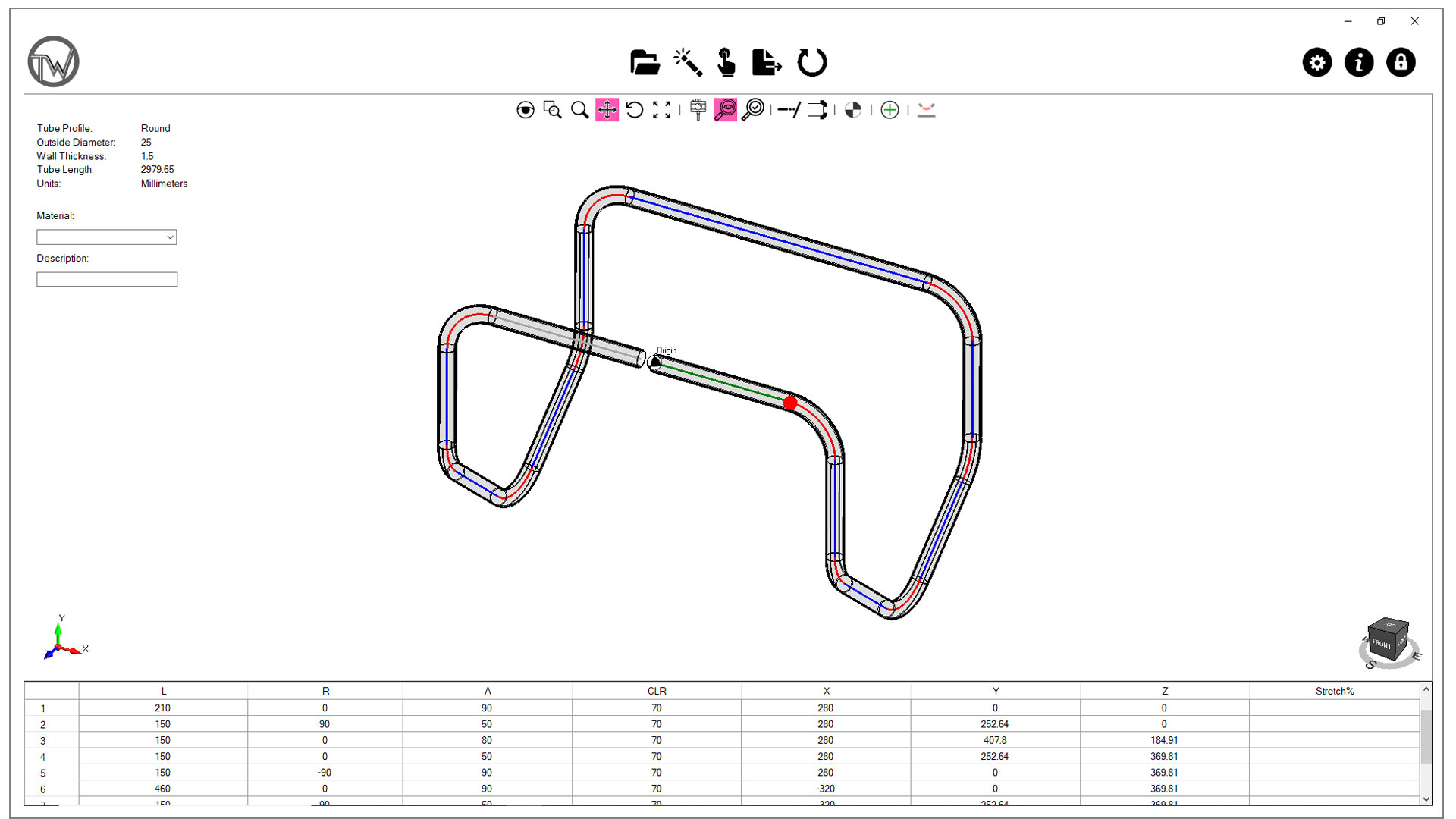

Simply select the first straight part of the tube loaded from your file and in a second, you will be able to view the cycle program data.

It allows the extraction of bending data for those geometries that present data extraction problems and difficulties, a manual procedure but extremely quick to use in those cases in which the file shows anomalies.

Possibility of extending the endpoint of the central line till the end of the tube, extremely useful in case of pipes with worked ends.

LRA + XYZ extraction from the assembly by selecting only the components of interest.

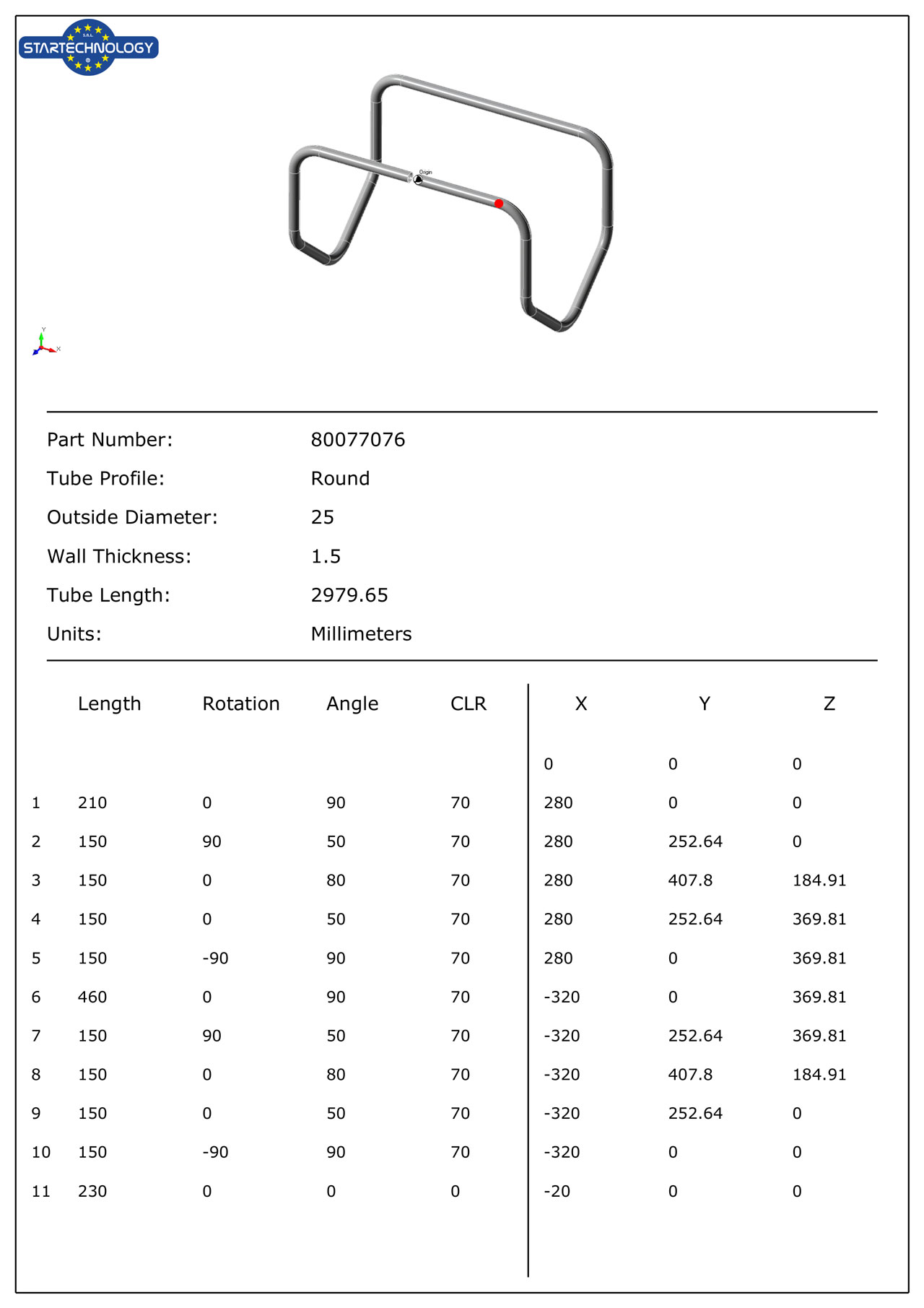

Export of bending data in a detailed PDF page or direct transfer to the bender PLC.

Possibility to extract values from round, square or free form pipe.

Extremely smart and user-friendly interface, no training costs, production starts from the first minute after the installation.

On-line support with video training available on youtube for free. Service and support always available included in the contract and renewable.

Start from your idea, build your project!

Create your 3D model (.stp, .igs, .dwg, .dxf) or extract a single component from an assembly.

Click, import the STEP or IGES wait two second and enjoy the result!

Now you just have to decide if send the program to the bender or print a PDF file with the bender data to be archived or sent to production, obviously customizable with your LOGO.

Great! You have chosen to transfer the data straight to the STAR tube bender! We always guarantee the maximum result with the minimum waste of material thanks to our 3D simulation with collision detection and cycle analysis.

Now all you have to do is turn your projects into reality!