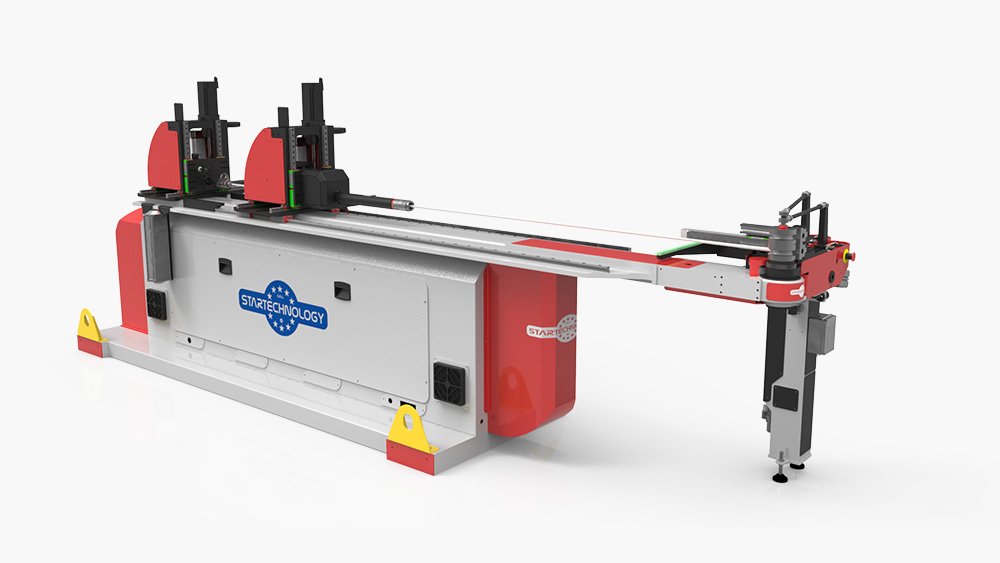

The production line of FULL BEND 650, due to its size and capacity, is the most suitable machine for various sectors that use a range of tubes of different sizes in different materials and can range in any field of application: metal furniture ,industrial plant engineering, agriculture, boating, motoring, plane, etc.

The FULL BEND 650 pipe bending machine line proves to be extremely versatile and its flexibility of capacity and production capacity is the only challenge of its kind. Available in different ways with others, with an energy saving system with a maximum of 42% of absorbed potential. The control system via graphical interface allows creating cycles of files and simulation in 3D.

ISO certified system 9001:2008

ISO certified system 9001:2008

Made in Italy

Made in Italy

Technical sheet

Automation levels

FULL BEND 65-6-2P

Caratteristiche

| Axe | Position | Name | Type |

| 1 | Y | BEND | BRUSHLESS |

| 2 | XM | FORWARD | BRUSHLESS |

| 3 | XS | FORWARD | BRUSHLESS |

| 4 | Z | ROTATION | BRUSHLESS |

| 5 | W | MANDREL MOVEMENT | BRUSHLESS |

| 6 | K | POSITION MOVEMENT. | BRUSHLESS |

| 7 | AS | TUBE SUPPORT | BRUSHLESS |

| 8 | M | CLAMP | HYDRAULIC |

| 9 | C | SHOULDER | HYDRAULIC |

| 10 | AN | MANDREL | HYDRAULIC |

| 11 | PI | COLLET | HYDRAULIC |

| 12 | P | HIGH POSITION | HYDRAULIC |

| 13 | A | HIGH MANDREL | HYDRAULIC |

| 14 | S | FOLLOWING | HYDRAULIC |

| 15 | RM | DIE RETURN | HYDRAULIC |

FULL BEND 65-9-MP

Caratteristiche

| Axe | Position | Name | Type |

| 1 | Y | BEND | BRUSHLESS |

| 2 | XM | FORWARD | BRUSHLESS |

| 3 | XS | FORWARD | BRUSHLESS |

| 4 | Z | ROTATION | BRUSHLESS |

| 5 | W | MANDREL MOVEMENT | BRUSHLESS |

| 6 | K | POSITION MOVEMENT | BRUSHLESS |

| 7 | P | HIGH MANDREL | BRUSHLESS |

| 8 | A | HIGH TUBE | BRUSHLESS |

| 9 | AS | TUBE SUPPORT | BRUSHLESS |

| 10 | M | CLAMP | HYDRAULIC |

| 11 | C | SHOULDER | HYDRAULIC |

| 12 | AN | MANDREL | HYDRAULIC |

| 13 | PI | COLLET | HYDRAULIC |

| 14 | S | FOLLOWING | HYDRAULIC |

| 15 | RM | DIE RETURN | HYDRAULIC |